Services

Filler Masterbatch

Filler masterbatch is widely used in the production of plastic products. It consists of a blend of calcium carbonate (CaCO₃), plastic resin pellets, and specialized additives tailored to meet customer requirements.

Advantages of Aramco Filler Masterbatch

Aramco’s filler masterbatch offers several key benefits:

- Cost Reduction: Lowers raw material consumption, thus reducing production costs.

- Enhanced Product Properties: Improves hardness, impact resistance, and product stability.

- Processing Efficiency: Stabilizes production processes and enhances surface quality.

- Energy Savings: Due to the high thermal conductivity of calcium carbonate, it helps reduce energy consumption during processing.

Types of Filler Masterbatch from Aramco

1. Polyethylene Filler Masterbatch

- A blend of calcium carbonate and additives within a polyethylene resin carrier.

- Helps lower material costs by partially replacing virgin polyethylene resin.

2. Polypropylene Filler Masterbatch

- Composed of calcium carbonate, polypropylene resin, and performance-enhancing additives.

- Delivers significant cost savings in production.

3. High-Impact Polystyrene (HIPS) Filler Masterbatch:

- A blend of calcium carbonate, HIPS resin, and specialized additives.

- Provides excellent whiteness, dispersion, and compatibility.

4. Transparent Filler Masterbatch

- Incorporates barium sulfate (BaSO₄) with plastic resins and special additives to reduce costs and improve mechanical properties.

Applications of Filler Masterbatch

Discover high-quality additives for agricultural plastic films, designed to enhance...

Plastic is an essential material in countless products, from packaging...

Many manufacturers use PP raffia due to its outstanding properties...

Black masterbatch is one of the most common plastic choices...

color masterbatch

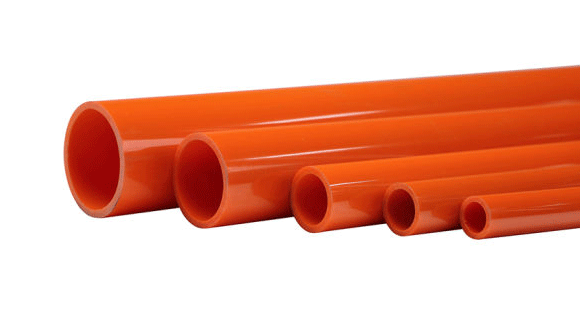

Color masterbatch is an essential material used to impart color to plastic products, ensuring they meet aesthetic requirements. The production process involves blending high-quality pigments, base resin, and specialized additives, followed by granulation to produce the final color masterbatch.

The key advantages of Aramco color masterbatch include superior dispersion on the surface of finished products, consistent color shades, and excellent heat resistance. Additionally, processing with color masterbatch generates less dust, minimizes air pollution, and reduces material loss compared to using pigment powders. This leads to increased processing efficiency, reduced production time, and cost savings.

Due to these benefits, Aramco color masterbatch is widely used in various industrial processes such as film blowing, injection molding, extrusion, and more. As a reliable supplier, Aramco offers a wide range of color masterbatches, including white, black, red, gray, purple, blue, brown, orange, and yellow. We also provide specialized color masterbatch solutions with custom effects tailored to meet specific product requirements.

Outstanding benefits of color masterbatch

Aramco’s Color masterbatch offers several key benefits:

- Create exact colors as end-products’ requirements

- Great dispersion

- High color fastness and good thermal resistance

- Environmental friendly

- Various color choices

Application For Color masterbatch

Discover high-quality additives for agricultural plastic films, designed to enhance...

Plastic is an essential material in countless products, from packaging...

Many manufacturers use PP raffia due to its outstanding properties...

Black masterbatch is one of the most common plastic choices...